| Engine Technical spectifcations |

SELECTING THE CORRECT CARBURETOR SIZE

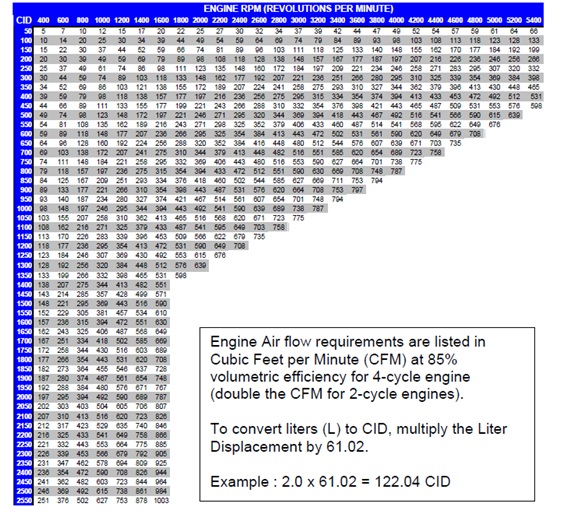

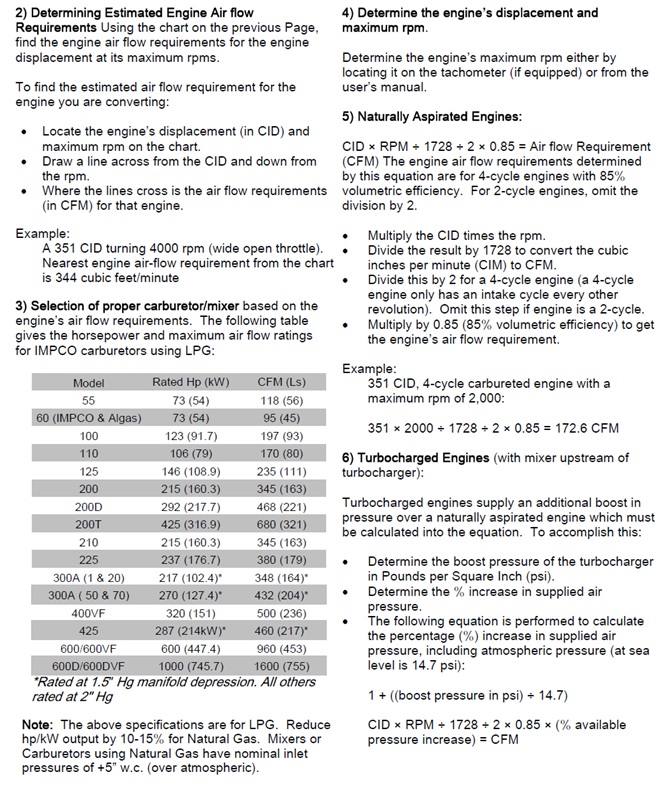

Air-Flow Capacities It is important to correctly match the air-flow capacity of the IMPCO carburetor/mixer to the engine air-flow requirement. If the carburetor/mixer is too small, then the power output of the engine will be limited. Conversely, a carburetor that is too large for an engine will create problems with idle stability and inconsistent fuel mixtures, especially at low speed. As a general rules, the air flow capacity of the carburetor should be reasonably close to the air flow requirement of the engine. If a carburetor is not available that matches the engine’s air flow requirements, then it is usually recommended to use a larger carburetor than a smaller one (round the CID up). In general, use a smaller carburetor for maximum efficiency and a larger one for maximum power.

Consider these options when determining your carburetor/mixer needs. The type of service the engine provides is another necessary consideration in selecting the appropriate carburetor (or mixer). An engine which is never operated at wide open throttle provides the best performance and service using carburetion, such as lift trucks and some passenger car applications.

These engines have a degree of under carburetion, are easier to start and will develop the low end torque required suited for this type of service. Engines used in high rpm ranges can be equipped with carburetors delivering somewhat over the air-low capacity dictated by the engine’s air-flow requirement and the larger capacity carburetor will be able to respond to maximum air-flow requirements.